Horseshoe shape corrugated steel pipe High Quality Manufacturer

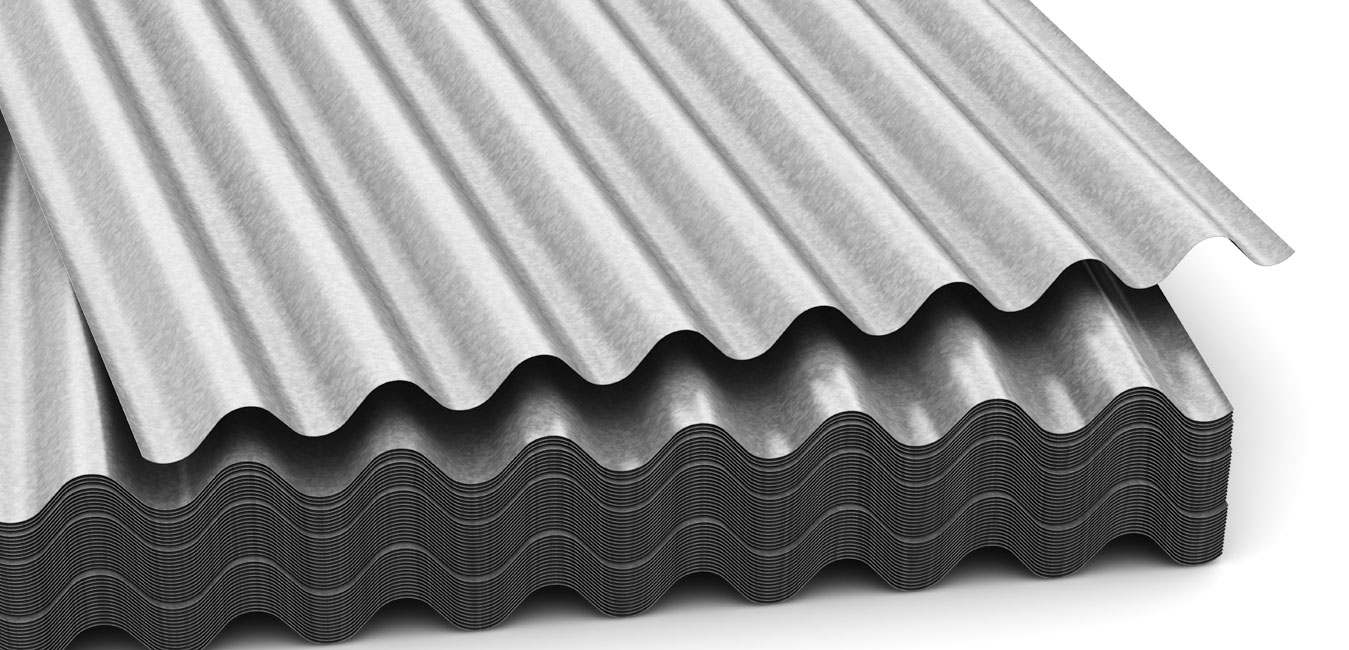

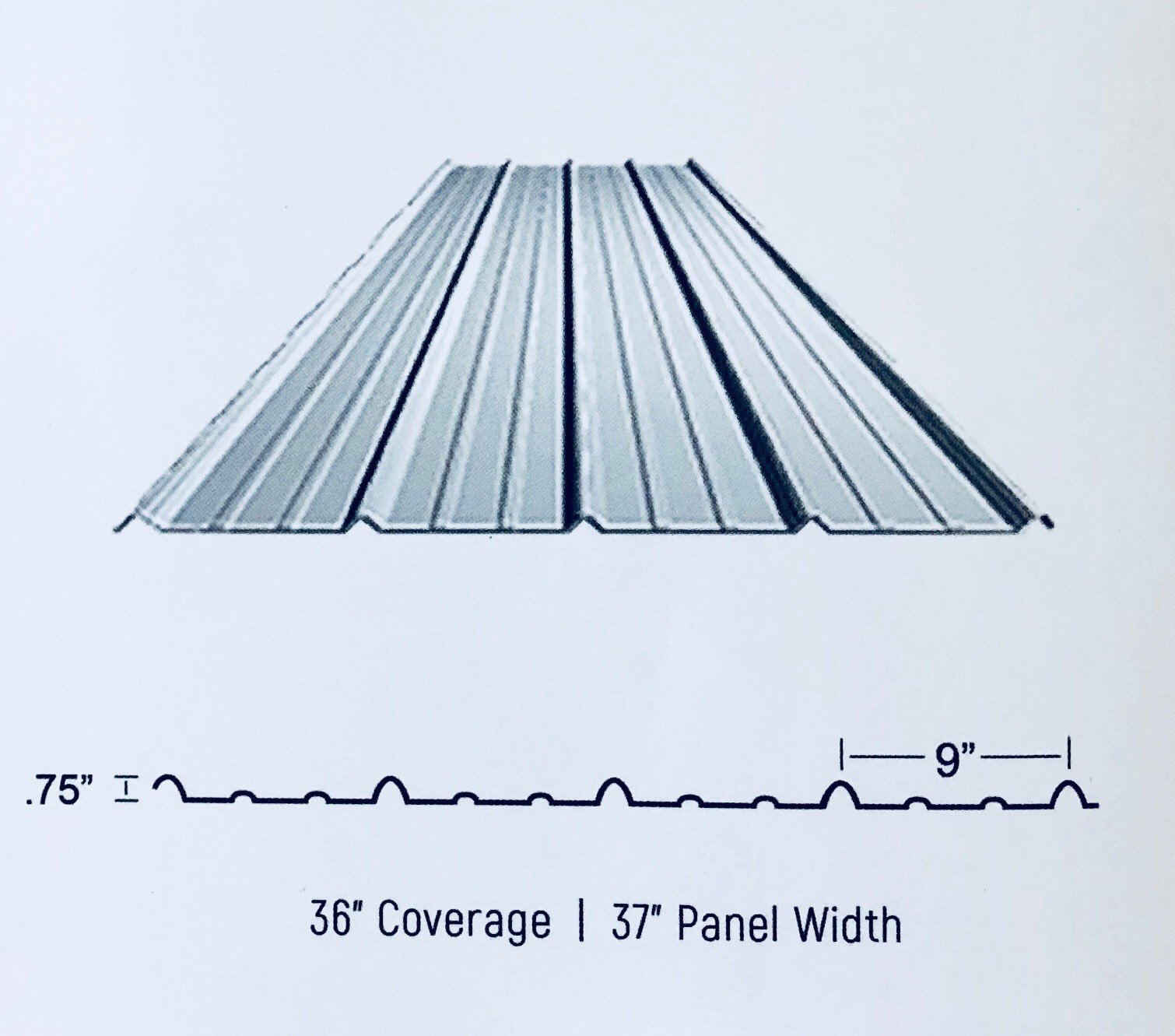

The traditional shape of corrugated sheet metal is round and wavy. It is low-cost, lightweight, durable, energy-efficient, long-lasting, and easy to install. Due to its enhanced durability and aesthetics, corrugated metal roofing has become increasingly popular over conventional roofing materials such as asphalt shingles and clay tile.

Horseshoe shape corrugated steel pipe High Quality Manufacturer

The natural shape of a corrugated metal panel gives it a structural advantage over a Standing Seam or R Panel of the same base material. The consistent corrugation helps hide small imperfections that occur over time from weather or impacts. For these reasons, corrugated metal systems have been used across the country for years.

.jpg?v=f84ead64&mode=h)

Corrugated Sheets New Box Profile Option Now Available

Shapes and uses of corrugated conduits: Shape: Range of Sizes: Common Uses: Round: 6 in. -51 ft: Culverts, subdrains, sewers, service tunnels, etc. All plates same radius. For medium and high fill (or trenches) Vertical ellipse 5% nominal: 4-21 ft nominal;before elongating:

Corrugated Metal Roofing Company Corrugated Metal Roof Repair

Corrugated metal sheets are widely used in various industries and applications due to their exceptional strength, durability, and versatility. These sheets are made of metal panels with parallel ridges or corrugations that provide added rigidity and strength.

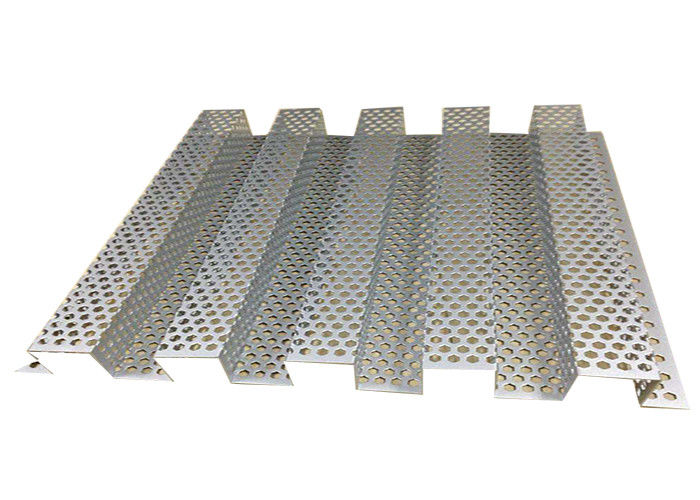

Hexagonal berlubang Aluminium Sheet Artistic Corrugated Shape Moisture

For starters, corrugated boxes are susceptible to inclement weather, such as rain or snow. The packaging can become deformed or lose its shape. But the biggest drawback of using corrugated cardboard is its cost. Compared to other options, corrugated is on the higher side of the price range, which may be disheartening for companies with a lower.

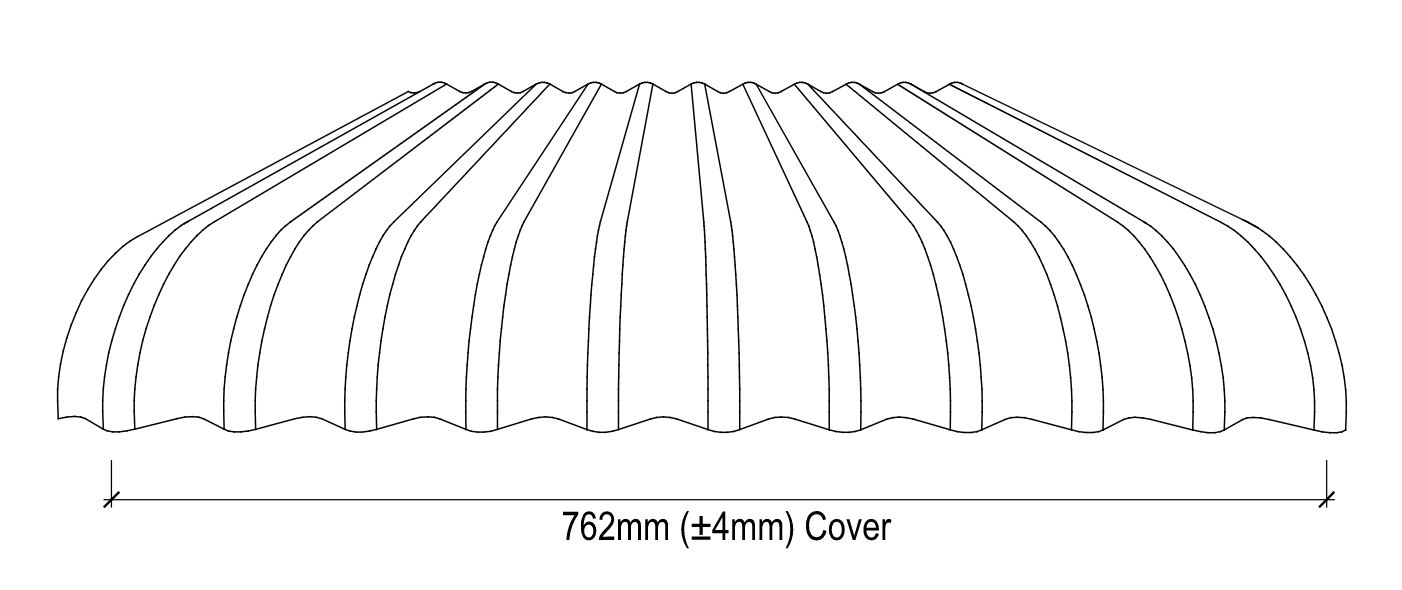

Stramit® Curved Corrugated STEEL SELECT®

Corrugated boxes can be used to ship and store almost any product, both consumer and industrial. As with folding cartons, there are seemingly endless corrugated box styles available. Before you read this article, it may be helpful to read about what corrugated boxes actually are first: click here.

The mesh configuration of corrugated steel shear wall with (a

WestRock's corrugated packaging is one of North America's leading, vertically integrated manufacturers, offering a broad range of converting capabilities and high-quality corrugated materials and machines designed to protect, promote, deliver and display your products.. Whether you need a unique shape, a special reinforced structure, a.

H14 750mm Aluminium Corrugated Roofing Sheets / Panels Industrial

The most common flutes used today are A, B, C, E, and F with A being the largest. Your flute size determines the thickness of the walls of your corrugated box as well as the stacking strength. "A" flute was the original corrugated flute and is the thickest flute profile you can use. An A flute is roughly 5mm thick, and is an excellent.

Corrugated Polycarbonate Sheet Aegis Marketing Msia's Leading

What Is Packaging Certification Testing? Order Custom Packaging Today! What Paper Is Used In Corrugated? Kraft and test paper are the two most common types of paper used in corrugated boxes. The interior liner of the box is usually made of test paper, while the exterior liner is made of kraft paper.

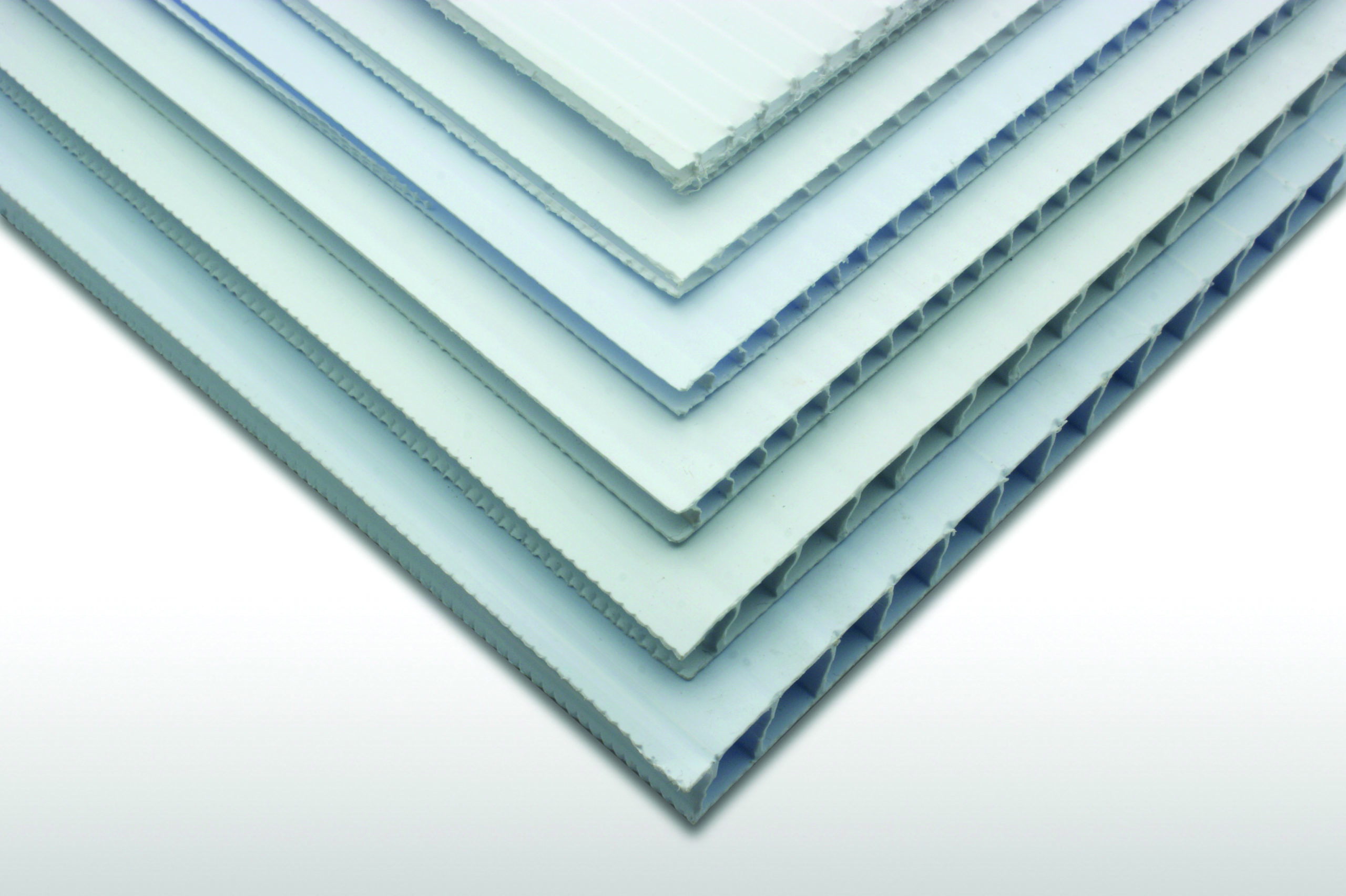

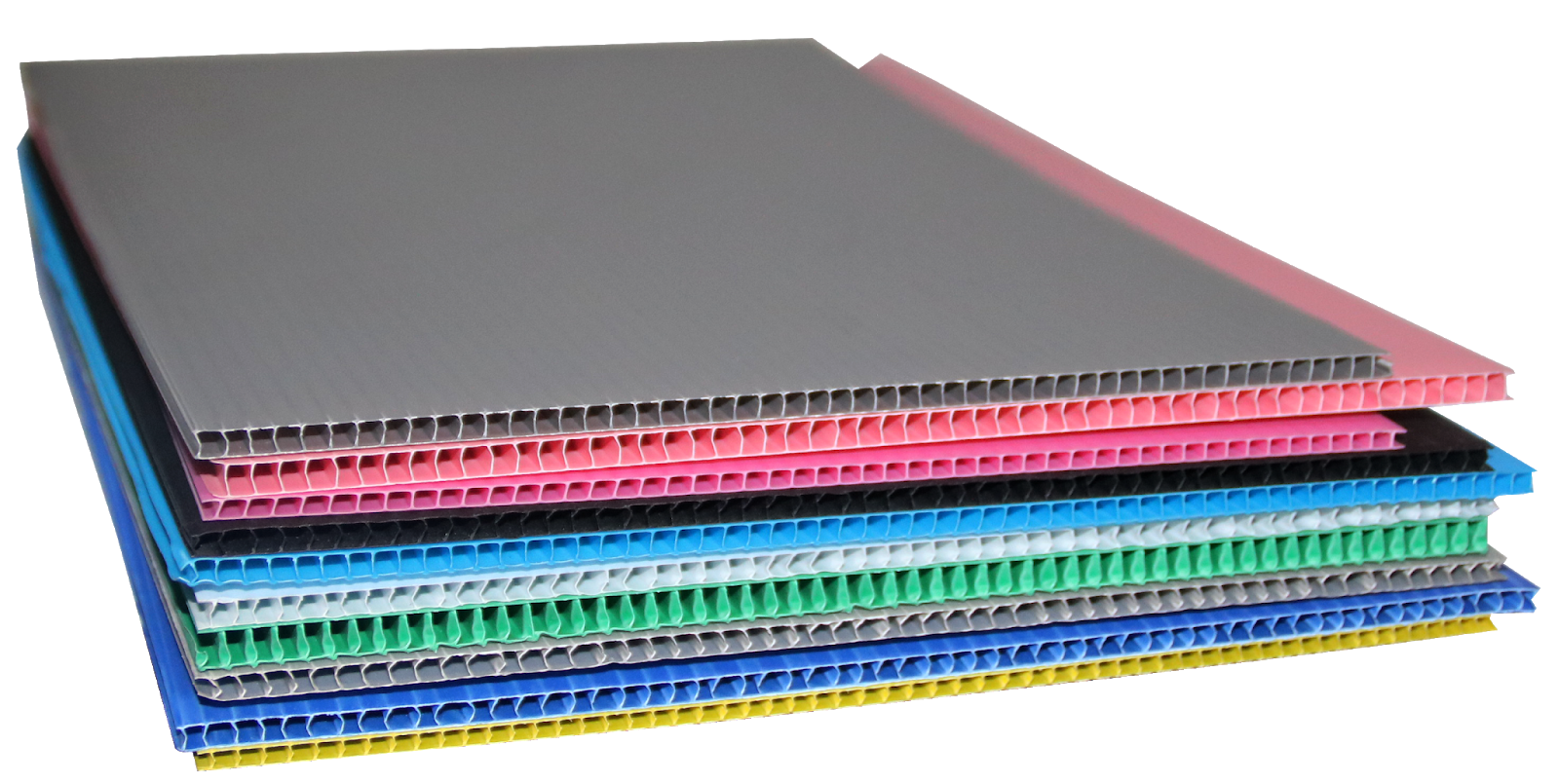

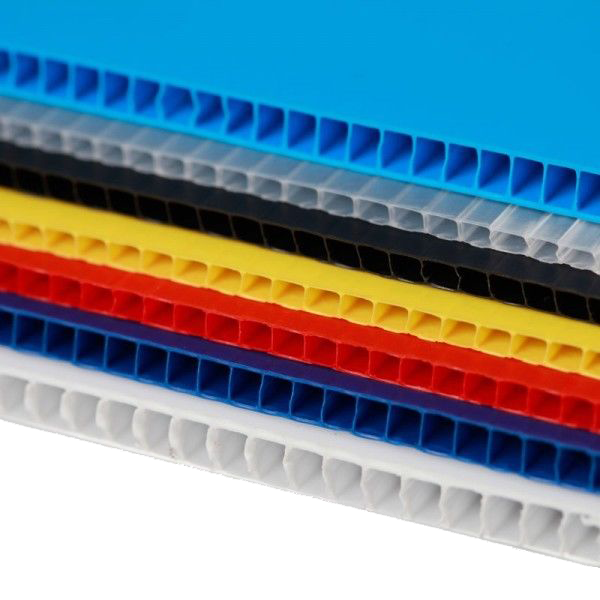

Polypropylene Twinwall (Corrugated Plastic Sheets)

Double-wall carton: This is a corrugated fiberboard carton made of three sheets of linerboard interleaved with two sheets of fluted corrugated material. Die Cutting: The process of cutting a corrugated sheet into a shape which will convert to the required box size when assembled. A rotary die cutter uses a cylindrical die and is generally.

G476027 Geometric Corrugated Shapes Pack of 276 GLS Educational

It's estimated that the U.S. shipment volume of corrugated packaging will be around 443 billion square feet in 2023. The corrugated board packaging market was valued at over $262 billion in 2019, and is expected to reach nearly $400 billion by 2025.

What is PP Corrugated Sheet?

(A) Single Face: One corrugated medium is glued to one flat sheet of linerboard; flutes exposed. (B) Single Wall: The corrugated medium is glued between two sheets of linerboard. Also known as doubleface. (C) Double Wall: Three sheets of linerboard with two mediums in between.

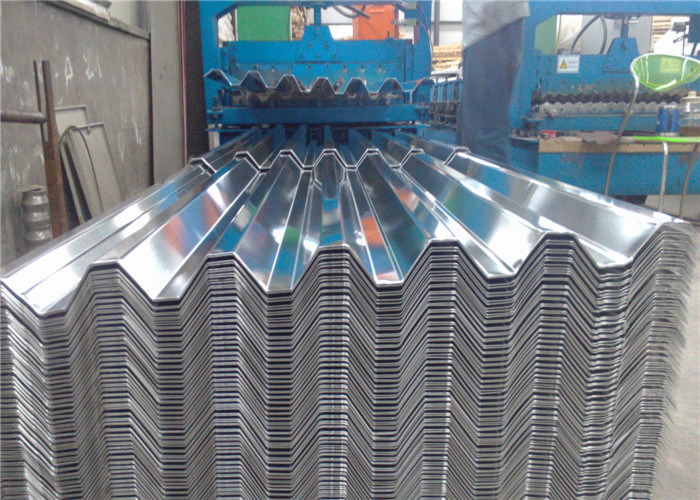

TSDPL Galvanized Corrugated Sheets Manufacturers

Today, corrugated metal sheets are typically made using a cold-form process. First, the process starts with a flat piece of metal which is then pressed into 3D corrugated patterns using a series of rollers. Then, different roller arrangements create different types of corrugation from the sizes of waves to the angles.

Corrugated Sheet Industrial Metal Supply

Cardboard is a thick paper stock (also called paperboard) used for creating attractive packaging and its inside dividers or lining. Typically it's used for food packaging like cereal boxes, small electronics like cameras, and even entertainment products like playing cards and board games.

Corrugated Box What Is It? How Is It Used? Types, Shipping

Flute Height: 1/32". E Flute vs F Flute. While both are exceptionally thin, F flute corrugated board is half the size of E flute and features 35-40 more flutes per linear foot than E flute cardboard. Being slightly thicker than standard paper, F flute is ideal for printing machines and easier to fold than E flute.

Corrugated plastic sheets

A corrugated box begins with corrugated board, which is a composite material made from two or more sheets of paperboard. The sheet that forms the center of a piece of corrugated board is called the medium: it's given a wavelike, corrugated shape and then glued between flat sheets called the liner or linerboard.